Mining, Oil and Gas Components

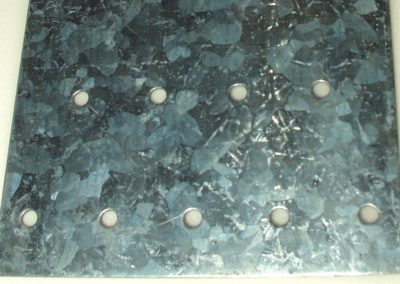

Plating to improve corrosion and wear resistance, hardness or lubricity of mining equipment and components

Protection and Prevention – metal surfaces

The surface of your components and equipment have an often overlooked role in the productivity and effectiveness of processing in the mining, oil, gas or other sectors. Surface protection can extend the useful life, and in-service cost, of a tool or product. Preventing corrosion from occurring may eliminate or reduce part replacement frequency (when maintained regularly).

Types of products that can be electroplated or treated to resist corrosion or wear include: Valves, Tubulars, Heat Sinks, Shafts, Drilling Components, Rollers, Dies & Moulds, Tooling, Pumps, Hardware & many more.

Fit for Purpose Surface Treatment

Electroless Nickel is our ‘go-to’ surface protection coating for mining, oil, gas, and water industry components – wherever there is high usage and a need to prevent corrosion, reduce wear or improve hardness and durability. However other plating finishes may provide adequate protection or wear resistance. Fit for purpose is the guiding principle for surface treatment selection. Whether that’s cleaning and pickling to remove rust, electroless nickel to prevent galling, or even zinc plating (sacrificial coating) for lower level protection. Please contact us for assistance in choosing the right finish for your components and the conditions they will be used in.

Please feel free to browse through the site to see the wide range of plating, finishing and other services you might benefit from.

Related processes

ONLINE QUOTE

We are no longer providing estimates for Metal Restoration work. If you are a manufacturer requiring finishing for your ready to plate commercial products or components click on "Quote for new parts finishing" and you will be directed to the business we sold our commercial plating operations to. Note - they DO NOT offer metal restoration or refurbishment services.