Zinc Plating

Zinc plating provides corrosion resistance for nuts, bolts, screws and fasteners

The information provided on this page is to inform you about some aspects of zinc plating as a metal surface finishing choice. A Class currently provides some, but not all, of the zinc plating finishes mentioned below.

About Zinc Plating

The primary purpose of zinc plating is to protect metals from the effects of corrosion or rust. Zinc Plated coatings are “sacrificial” coatings – meaning the coating sacrifices itself in order to protect the substrate beneath, as the coating oxidizes the corrosion itself continues to provide a level of protection to the substrate.

Zinc plating comes in different colours – but each of the colours can result from the type of plating formulation used – meaning that they do not necessarily have the same resulting corrosion resistance properties as each other. Further, zinc plating types also vary in their ability to protect from both “red” (iron related) and “white” (alloy related) corrosion types – though we will not explore that any further here (call us if you wish to know more).

The following briefly describes some of the common zinc colours/types:

Zinc Gold Passivate

Yellow Zinc (Gold Zinc) is the most common type of zinc plating used in automotive parts finishing. Gold is its colour only – it does not contain actual gold. Of all the zinc types it retains a good average level of corrosion resistance.

Black Zinc

Some suppliers use a black oxide coating or dye over the surface of zinc plating (e.g. olive drab) and call it black zinc. Others use formulations that are actually black plated. The level of corrosion resistance of the latter will be somewhat lower than that of gold zinc – but better than clear passivate. The oxide-coated versions will tend to offer slightly better resistance due to the additional coating and depending on the underlying type of zinc used.

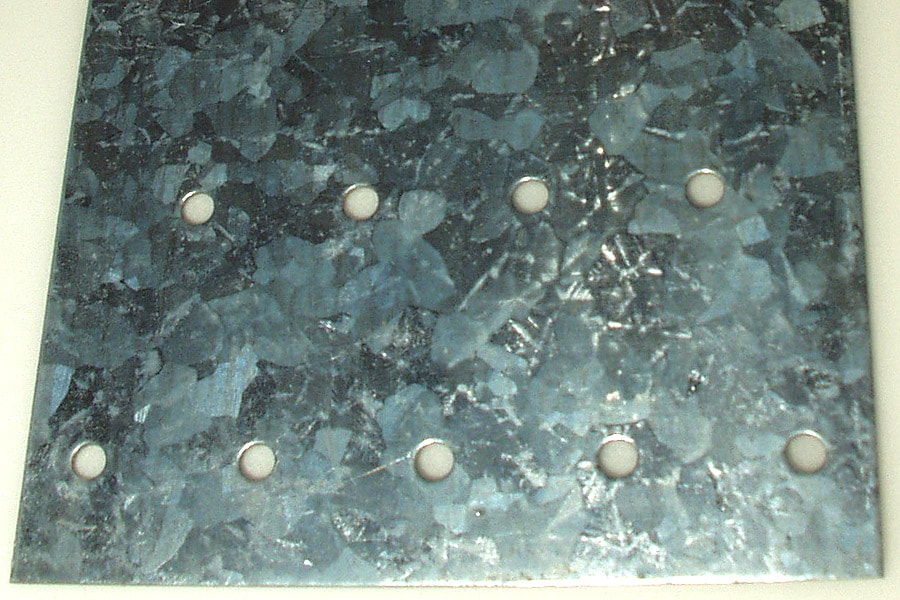

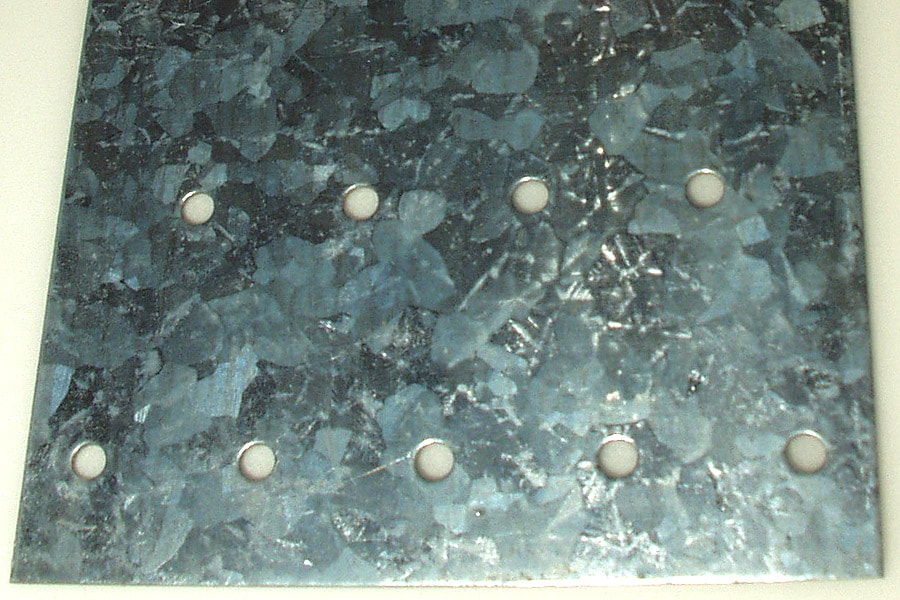

Blue or Clear Zinc

Though clear zinc, you would imagine, has no colour, often it is referred to as blue as it can result in a blue-ish hue. This type of coating is often achieved by tri-valent based processes which are more environmentally friendly than the hex-valent versions but offer lower corrosion resistance properties.

Zinc cobalt

Cobalt zinchas been said to offer more than 5 times the corrosion resistance of other zinc types and is very ductile. It is a plated alloy of the two metals and in some cases it can be provided in colours of olive, blue, black or gold.

Acid zinc

Acid zinc plating does not use cyanides in the process (sometimes used in alkaline types). It’s advantages as a finish (over other types) include brightness, ability to plate otherwise difficult to plate substrates, and lower levels of hydrogen embrittlement of parts.

A Class Metal Finishers offers a range of zinc plating services, including some of the above. Please contact us for more details.

Alternatives to Zinc Plating for Corrosion Resistance

Depending on your need, A Class can offer advice on zinc plating, or alternatives such as electroless nickel plating, for achieving corrosion resistant outcomes. Please call us to receive expert advice on selecting the right plating finish for your job.

ONLINE QUOTE

We are no longer providing estimates for Metal Restoration work. If you are a manufacturer requiring finishing for your ready to plate commercial products or components click on "Quote for new parts finishing" and you will be directed to the business we sold our commercial plating operations to. Note - they DO NOT offer metal restoration or refurbishment services.