Nickel – Electroless

ELECTROLESS nickel plating for wear resistance and corrosion protection in engineering

Description of Nickel Plating (Electroless)

Electroless nickel plating is not a new process. In its infancy electroless nickel was primarily used in the electronics industry. There are many more applications now – for increasing hardness, or wear resistance, as well as increasing corrosion resistance and lubricity. As manufacturers, it is worthwhile you understanding these benefits – which can add very real value to parts, components and equipment in industries such as mining, oil & gas, electronics, water treatment, marine and more.

Unlike electroplating, electroless nickel plating does NOT require electrical current to deposit metal onto a substrate. Nickel is deposited to the surface metal via what’s called an ‘autocatalytic’ process, which deposits the coating in uniform density to the surface being plated. (ELECTRO-plating does not cover parts uniformly).

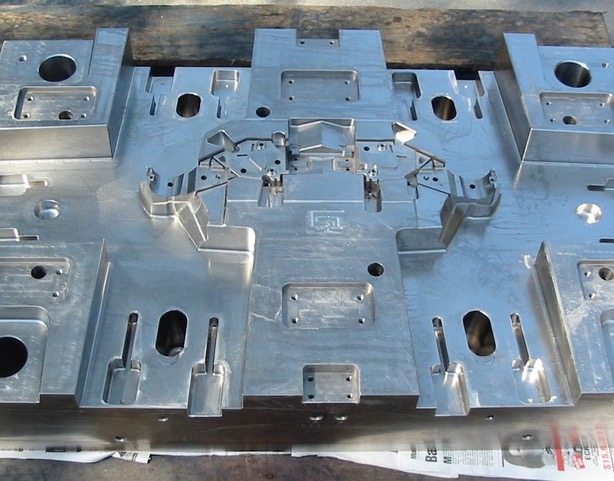

The electro-less nickel plating process has many advantages over ‘electrolytic’ processes in an engineering environment. The coating can be used where a hard, or corrosion resistant, finish is required. A major advantage of the process is the ability to coat the whole surface of an item EVENLY, including internal surfaces, unlike electrolytic processes, which have difficulty depositing into recessed and internal areas and can result in excessive buildups on points, corners, etc.

The electroless nickel process can provide significant savings when comparing to ‘Hard Chrome’ (an electrolytic process). To create an internal coating by electrolytic methods requires the use of complex anode arrangements which are generally costly to produce and setup. Machining after plating is often required, to return uniformity to part dimensions. With Electroless nickel, the coating will not distort the dimensions, so no post-machining is needed as long as allowance is made for the nickel coating at pre-machining stage.

Benefits of Electroless Nickel

UNIFORMITY of coating ensures threads, holes, recesses and internal areas all receive the same amount of plating as sharp corners, edges, flat surfaces and high points. The coating can also provide resistance to a range of chemicals.

Electroless Nickel coatings can provide WEAR RESISTANCE and CORROSION PREVENTION.

LUBRICITY – it is able to slide over other metal surfaces without galling (reduces wear, increases service life).

MOULD RELEASE – a good nonstick surface in many applications. Additives such as Teflon or Silicon Carbide can be included into the deposit to further increase the properties such as lubricity and wear resistance.

Can (like hardchrome) be machined. However, THE REQUIREMENT TO MACHINE BACK TO TOLERANCES IS OFTEN ELIMINATED by the ability to apply the nickel coating uniformly and in thicknesses that can maintain tolerances to within approx 10 mil.

ABRASION RESISTANCE can be good to excellent dependent on solution used and hardening processes applied.

An alternative to STAINLESS STEEL – parts can be manufactured in mild steel and coated with electroless nickel. Provides similar performance at lower cost.

HARDNESS – varied solution types can give a variety of as plated hardness. Heat treatment increases the hardness to a maximum of approx. 70 Rockwell C

Coating Applications

Valves, tubulars, heat sinks, shafts, drilling equipment, rollers, dies & moulds, tooling, pumps, impellers, drill bits, shovelling blades & more. Wherever there is need to prevent corrosion, reduce wear or improve hardness and durability.

Industries using Electroless Nickel coatings include

Mining; Oil & Gas; Automotive; Water; Defense & Aerospace; Food*; Electronics; General Industrial.

Design Cautions

Consider all surfaces of the item. Allow for an even surface tolerance. ‘Selective’ coating (coating only some surfaces of an item) is possible via masking of selected surfaces, however this will affect cost. Be as clear as possible about the surface quality and outcomes you expect in the finished product. Consult your finisher in relation to metal substrates this process is suited for. (*May not be suited to some food processing applications)

IMPORTANT INFORMATION FOR METAL PRODUCT ENGINEERS & DESIGNERS

In heavy industry and engineering environments, electroless nickel plating has many advantages over ‘electrolytic’ processes. Product engineers and designers are encouraged to consider “design for electroless nickel plating”, particularly for steel parts, to enable superior performance of equipment and save machining and wear costs.

(Some of the above information is based on the Nickel Development Institute publication “Properties and applications of Electroless Nickel”, Ron Parkinson, December 1997)

Please note that the above information is provided as a general guide only. Please talk to our plating team for more insights to the benefits of this unique and robust surface finishing process.

ONLINE QUOTE

We are no longer providing estimates for Metal Restoration work. If you are a manufacturer requiring finishing for your ready to plate commercial products or components click on "Quote for new parts finishing" and you will be directed to the business we sold our commercial plating operations to. Note - they DO NOT offer metal restoration or refurbishment services.